When exploring motor technologies, many professionals come across two commonly used types — brushed and brushless DC motor systems. Although they may appear similar in function, their internal structures and performance characteristics differ significantly. As an established manufacturer, Power Motor designs and customizes both types to meet diverse motion control needs, especially for applications that require precision, durability, and efficiency.

Construction and Operating Principles

A PMDC (Permanent Magnet DC) motor operates with brushes and a commutator that deliver current to the armature. This structure makes it simple and cost-effective but also introduces friction and periodic maintenance. In contrast, a BLDC (Brushless DC) motor replaces brushes with electronic commutation, enabling smoother operation, higher efficiency, and longer lifespan. The main difference between PMDC and BLDC motor types lies in how they transfer current and manage energy conversion—mechanical versus electronic.

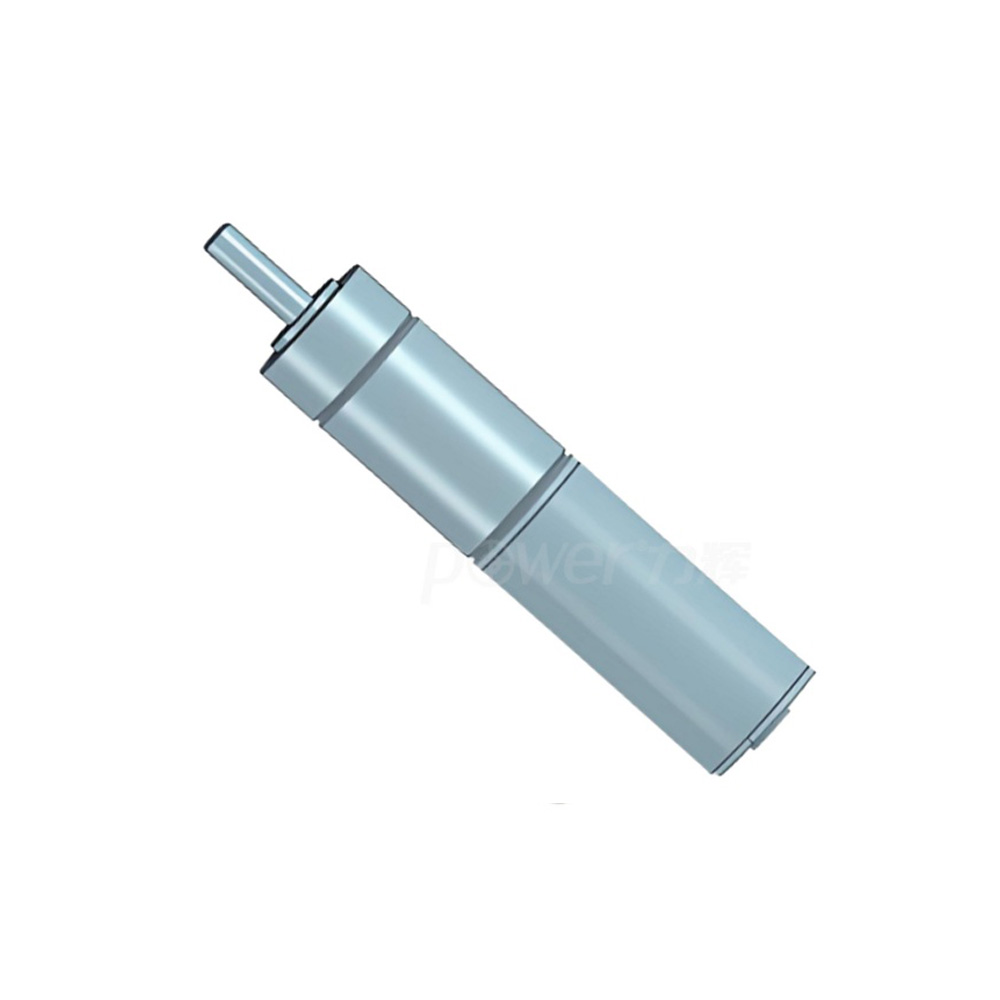

Example of a Custom Coreless Gearbox Motor

Among their diverse product range, Power Motor offers the Coreless Gearbox Motor, Model: PGM.P016M0172-01 (Voltage: 12V). This motor is known for its low noise, high-speed response, no cogging torque, long life, and lightweight design. It demonstrates how advanced design and precision assembly can deliver efficient, quiet, and reliable performance in compact motion systems—perfect for applications that demand accuracy and durability.

Conclusion

Although both brushed and brushless DC motor designs serve similar purposes, they differ in construction, efficiency, and longevity. Understanding the difference between PMDC and BLDC motor technologies helps users select the right system for their needs. With its dedicated customization platform, extensive technical expertise, and proven manufacturing capability, Power Motor continues to provide high-quality motion solutions that meet professional and industrial demands worldwide.